Sustainable windows - planning for the future

Sustainability is a desirable goal in any building activity - in new construction as well as in modernization. A great deal can be achieved here simply by installing modern windows. In addition to their effective thermal insulation, high-performance PVC-U windows can impress with their resource- and energy-saving production. And since they can be almost completely recycled, they also make a valuable contribution to greater sustainability at the end of their product life cycle.

Table of contents

- Sustainability: From economy to ecology

- A comprehensive perspective

- Resource conservation starts with the window profile

- Modern windows mean energy efficiency

- Recycling closes the material cycle

Sustainability: From economy to ecology

Sustainability is one of the defining issues of our time. In the private sector, but also in the economy, the importance of acting in a way that conserves resources is recognized. The construction industry is no exception - not least because the issue of sustainability plays a role in the decisions of those responsible for building. This applies to private clients as well as to industrial, commercial and public clients. In fact, the building sector can make a significant contribution to a more sustainable way of life and economy, especially with a view to greater climate protection. After all, it is responsible for 14 percent of all CO emissions in Germany , and the global share is as high as 38 percent.2

Ensure long-term benefits

As current as the concept of sustainability is, it is not new. It was first made explicit in the early 18th century, namely with regard to sustainable forestry. The requirement at that time was to cut only as much wood as would grow back in the same period of time. In this way, a shrinking of the tree population can be avoided and stable yields can be achieved in the long term. By analogy, the principle of sustainability can be generalized: All animate and inanimate components of the environment - apart from raw materials, for example, also soils and the atmosphere - should not be stressed more than their regenerative capacity allows.

A comprehensive perspective

Strict application of this principle to the construction industry would mean that a building would require as little energy as possible overall and that ultimately only raw materials would be used that can be regrown or recycled. Material efficiency is thus added to the much-discussed energy efficiency, and the useful life is supplemented by construction and demolition. Such a comprehensive and at the same time detailed overall balance can be drawn up all the more easily because individual balances are already available for many building materials, building components and energy sources.

Resource conservation starts with the window profile

The example of the window is a good illustration of the factors that influence the sustainability balance of a building element. It all starts with the production of the window profiles. In the case of PVC-U windows, they are made from a PVC compound, the synthesis of which in turn requires petroleum products and rock salt. As a result of modern window recycling, however, virgin PVC can increasingly be replaced here by high-quality PVC recyclate, and without any loss of quality. In profile production at VEKA, the proportion of this sustainable recycled material is already 26 percent.

The technically demanding profile extrusion also offers various starting points for more sustainability in terms of energy requirements. As part of company-wide initiatives, electricity consumption at VEKA has been halved in around 15 years. The company's own idea management system has played a major role in this: employees know their workplace inside out and repeatedly provide suggestions for successful optimization. However, the fact that the extrusion lines require a lot of space also has a favorable effect - all the more electricity VEKA generates with photovoltaic systems on the hall roofs.

The system provider also minimizes water consumption with a specially created wetland biotope at its Sendenhorst headquarters. The process water for cooling the extrusion lines is taken from this biotope. It then flows back there, supplemented by rainwater, and is treated in the constructed wetland for reuse. The throughput of this circulation system is no less than 136 million litres per year.

Modern windows mean energy efficiency

Old buildings are typically equipped with very simple windows that do not yet have the performance of modern windows. A comparison illustrates the consequences: although windows in old residential buildings only make up about 10 percent of the building envelope, they account for up to 50 percent of heat losses. This makes modernization all the more effective, with the installation of heat-insulating, state-of-the-art windows - not least in terms of heating costs.

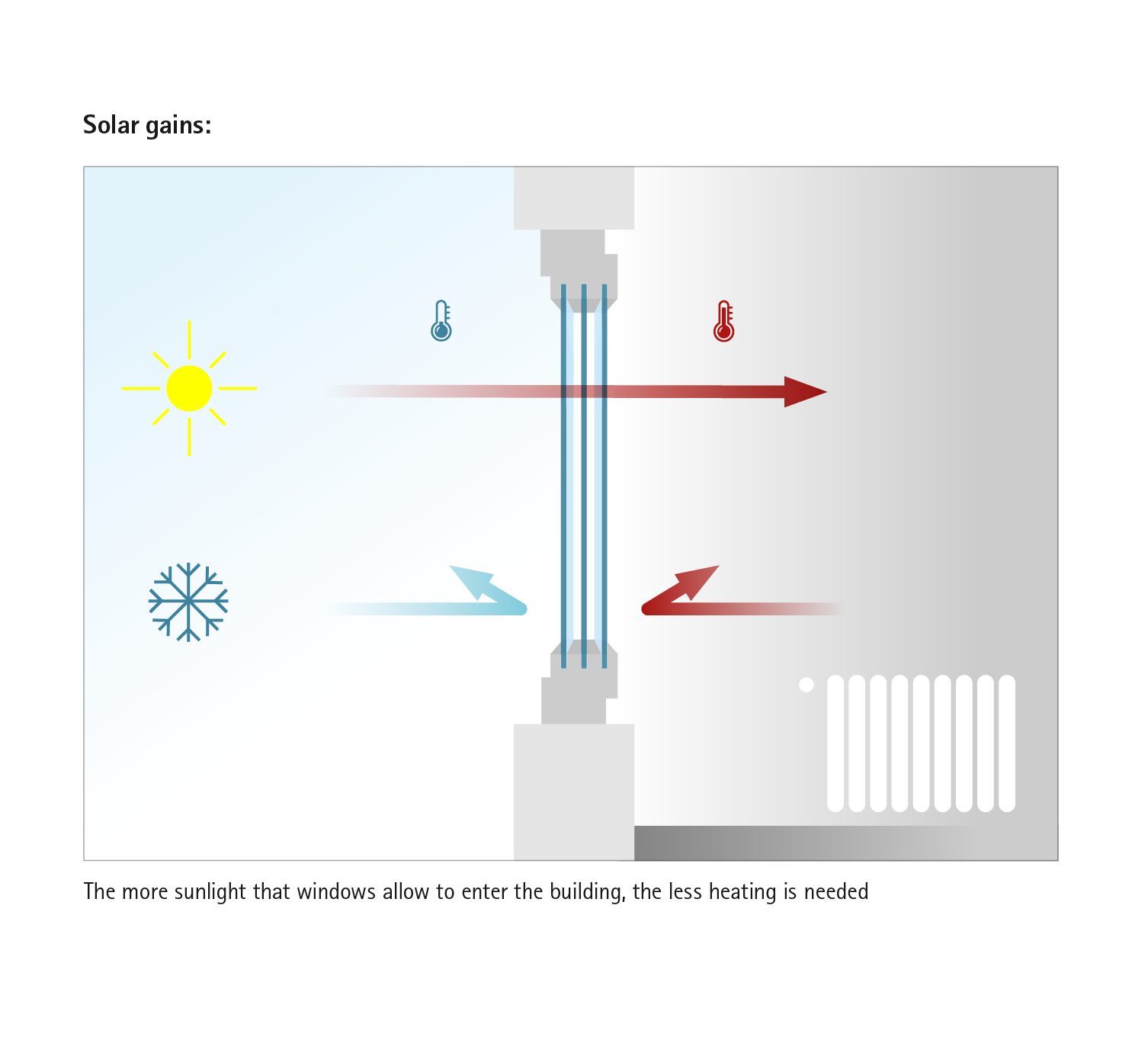

Windows not only prevent heat from escaping. The solar gains from incident solar radiation, whose thermal energy is then effectively retained in the building, can also noticeably reduce heating requirements. This is especially true for south-facing windows and balcony or patio doors, and here even more so for the generous elements of modern architecture. Excessive heating in summer can easily be prevented by elegant shading solutions.

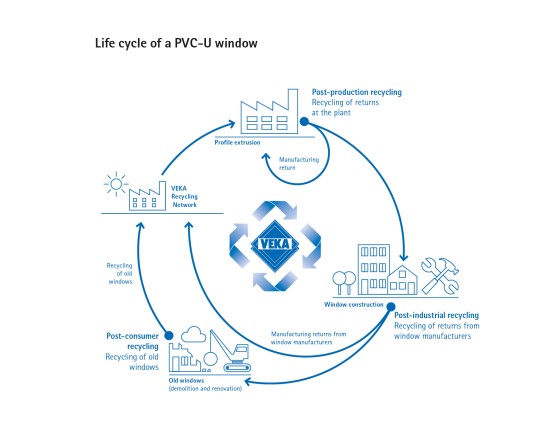

Recycling closes the material cycle

The sustainability balance of the window can only be complete if it also includes the phase after use. Windows made of all common frame materials can be recycled without any problems - apart from the energy savings due to the good thermal insulation over many years, this is one of the most important factors for their sustainability.

VEKA took the initiative in recycling PVC-Uwindows in 1993. At that time, the Group started up the first recycling plant for PVC windows and doors in Behringen, Thuringia. It was soon proven that PVC window recycling works very well and is also economically feasible. In the meantime, the plant in Thuringia has been joined by two others in the UK and France. The combined annual capacity of the three plants is 100,000 tonnes of old windows and doors as well as shutters and profile sections made of PVC-U.

The recycling process developed by VEKA delivers PVC granulate that is almost pure in terms of colour and type and can be fed directly back into the production of new window and door profiles without any loss of quality. In addition, ferrous and non-ferrous metals, glass and sealing rubber accumulate as further material fractions, which in turn can be fed into a new use. In this way, the entire PVC-U window is effectively reused: The material cycle is thus closed and new PVC-U windows can be manufactured in a way that is all the more resource-efficient, which further increases their sustainability.